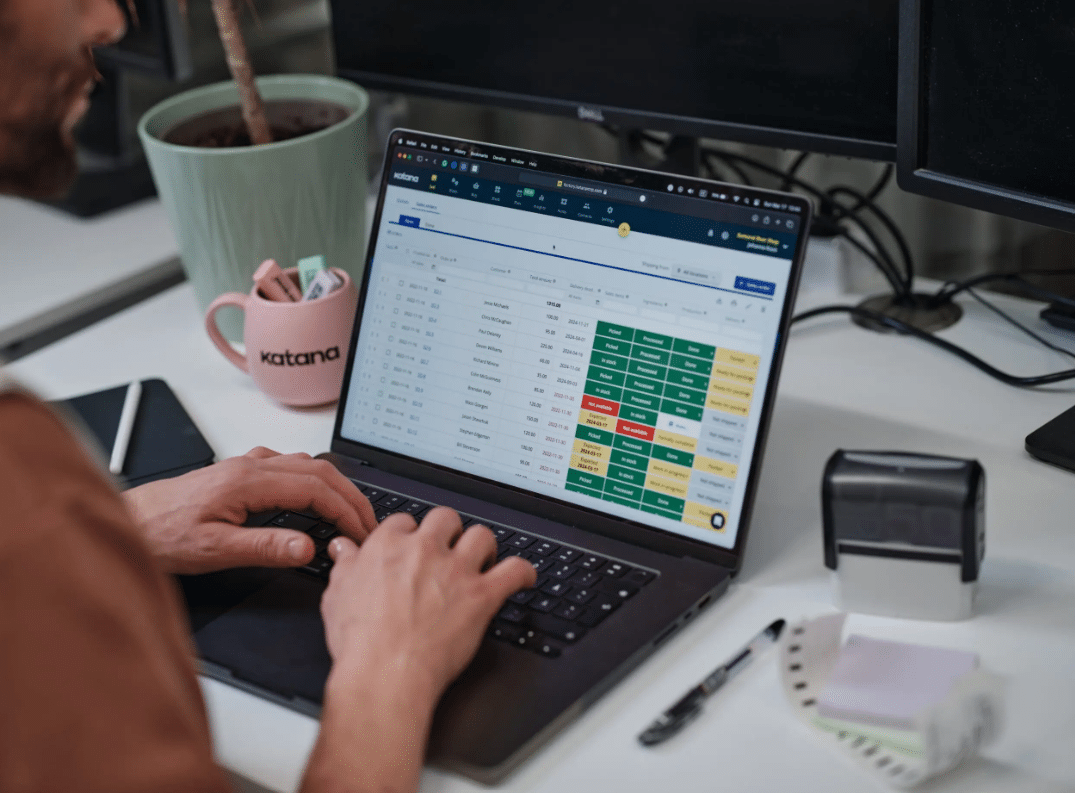

MRP Software: Enhancing Manufacturing Efficiency and Production Planning – In today’s fast-paced and competitive manufacturing environment, businesses need to stay agile and efficient to maintain profitability and meet customer demands. One of the most effective tools available to help manufacturers achieve these goals is MRP software or Material Requirements Planning software. This technology plays a critical role in streamlining production processes, managing inventory, and ensuring that materials and resources are available when needed. In this article, we will explore the features, benefits, and importance of MRP software in modern manufacturing and how it can drive operational efficiency.

What is MRP Software?

Material Requirements Planning (MRP) software is an integrated solution designed to assist manufacturers in managing their production processes, inventory, and supply chain. MRP software helps businesses determine the amount of raw materials, components, and subassemblies needed for production and when these materials should be ordered or replenished. By doing so, it ensures that manufacturers have the right materials at the right time, which reduces waste, minimizes production downtime, and improves overall efficiency.

MRP software typically includes tools for inventory management, demand forecasting, production scheduling, and order management. It works by analyzing the bill of materials (BOM), current inventory levels, and production schedules to generate material and component requirements. Additionally, it helps optimize manufacturing operations by reducing excess inventory, controlling lead times, and improving the accuracy of production planning.

Key Features of MRP Software

MRP software provides a wide range of features that enable manufacturers to streamline their operations and improve productivity. Below are some of the key features of MRP software:

1. Inventory Management

Effective inventory management is essential for keeping production lines running smoothly. MRP software helps businesses track inventory levels in real time and ensure that the right materials are available when needed. The software automatically calculates the required inventory levels based on production schedules and demand forecasts, reducing the risk of stockouts or overstocking. This feature also helps companies optimize warehouse space, reduce storage costs, and improve cash flow.

2. Demand Forecasting

One of the main challenges in manufacturing is predicting future demand. MRP software helps manufacturers forecast demand more accurately by analyzing historical data, customer orders, and market trends. This forecasting capability ensures that businesses have the right amount of materials on hand to meet production needs without overcommitting resources. By accurately forecasting demand, manufacturers can prevent shortages and minimize inventory holding costs.

3. Production Scheduling

Production scheduling is a critical aspect of manufacturing operations, as it directly impacts delivery times and customer satisfaction. MRP software allows manufacturers to schedule production runs based on material availability, machine capacity, and workforce requirements. The software can automatically create production schedules, allocate resources, and prioritize orders, ensuring that products are produced on time and within budget.

4. Bill of Materials (BOM) Management

A Bill of Materials (BOM) is a detailed list of all the raw materials, components, and subassemblies required to manufacture a product. MRP software manages the BOM to ensure that all necessary materials are available when production begins. The software can generate detailed BOMs based on product specifications and designs, enabling manufacturers to quickly identify material requirements and avoid production delays caused by missing components.

5. Supplier Management

MRP software helps manufacturers manage relationships with suppliers by tracking orders, lead times, and supplier performance. It allows businesses to create and send purchase orders automatically based on material requirements, reducing the risk of errors and delays. By integrating supplier data with the production schedule, MRP software ensures that materials arrive on time and in the correct quantity, minimizing disruptions in the manufacturing process.

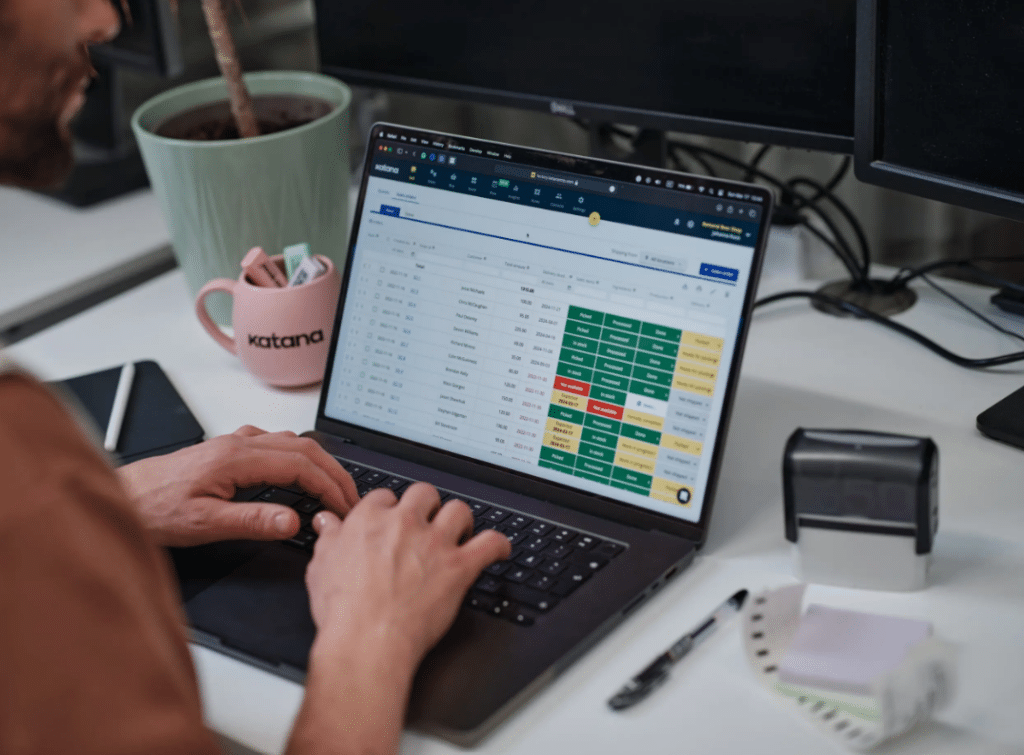

6. Real-Time Data and Reporting

MRP software provides real-time insights into production and inventory levels, enabling manufacturers to make informed decisions. With real-time data, businesses can quickly identify any issues, such as material shortages, production delays, or equipment breakdowns. The software also generates reports that help businesses monitor key performance indicators (KPIs), such as inventory turnover, production efficiency, and order fulfilment.

7. Cost Management

Cost control is an ongoing challenge for manufacturers, and MRP software can help businesses track and manage production costs more effectively. By monitoring material usage, labour costs, and overhead expenses, MRP software provides valuable insights into cost-saving opportunities. The software can also help manufacturers reduce waste, optimize production runs, and negotiate better pricing with suppliers.

Benefits of MRP Software

MRP software offers numerous benefits to manufacturers, from reducing costs to improving operational efficiency. Below are some of the key benefits:

1. Improved Efficiency

By automating production planning, inventory management, and demand forecasting, MRP software helps businesses streamline their operations and eliminate inefficiencies. Manufacturers no longer need to manually track inventory levels, place orders, or create production schedules, which frees up time for employees to focus on more strategic tasks. The result is improved productivity and faster production cycles.

2. Reduced Inventory Costs

Maintaining an optimal inventory level is crucial for reducing costs and improving cash flow. MRP software helps businesses minimize excess inventory by automatically calculating the required materials based on demand forecasts and production schedules. This ensures that businesses only order the materials they need, reducing storage costs and freeing up capital that can be reinvested in other areas of the business.

3. Better Production Planning

MRP software improves production planning by providing real-time data on material availability, machine capacity, and workforce requirements. This enables manufacturers to schedule production runs more effectively, minimize downtime, and meet customer delivery deadlines. With better production planning, manufacturers can optimize resource utilization, improve throughput, and reduce lead times.

4. Enhanced Customer Satisfaction

Timely deliveries and consistent product quality are essential for customer satisfaction. MRP software helps businesses meet customer demands by ensuring that the right materials are available when needed and production schedules are optimized. By reducing lead times and avoiding stockouts, manufacturers can improve order fulfilment and enhance customer loyalty.

5. Better Decision-Making

MRP software provides manufacturers with real-time data and actionable insights into their operations. This data helps decision-makers identify trends, spot inefficiencies, and make informed decisions about production, inventory management, and procurement. With better decision-making capabilities, manufacturers can improve their overall performance and stay competitive in the market.

6. Scalability

As businesses grow, their production requirements become more complex. MRP software is scalable, meaning it can adapt to the changing needs of a growing company. Whether a manufacturer is increasing production capacity, expanding product lines, or entering new markets, MRP software can scale to accommodate these changes. This scalability ensures that businesses can continue to operate efficiently even as they expand.

How MRP Software Improves Supply Chain Management

Supply chain management is a crucial part of manufacturing, and MRP software plays a significant role in improving it. By integrating data from suppliers, inventory, and production schedules, MRP software enables manufacturers to coordinate their supply chain activities more effectively. It helps ensure that materials are ordered in a timely manner, reducing lead times and improving the overall flow of goods.

Additionally, MRP software provides manufacturers with greater visibility into their supply chain, enabling them to track supplier performance, monitor order fulfilment, and identify potential disruptions. With this information, manufacturers can make proactive decisions to mitigate risks and ensure a smooth flow of materials from suppliers to the production floor.

Conclusion

MRP software is an essential tool for manufacturers looking to optimize their production processes, reduce costs, and improve operational efficiency. By automating material requirements planning, inventory management, and production scheduling, MRP software helps businesses streamline their operations and meet customer demands more effectively. With features such as demand forecasting, real-time data, and supplier management, MRP software provides manufacturers with the tools they need to stay competitive in an increasingly complex and fast-paced market. Whether you are a small business or a large enterprise, MRP software can help you improve your manufacturing processes, reduce waste, and boost profitability.